Introduction to Surface Defect Detection in Industrial Products

Overview of Surface Defect Detection

In today’s highly automated industrial landscape, maintaining product quality is more critical than ever. Surface defect detection plays an essential role in ensuring that manufactured products meet stringent quality standards. Whether it’s identifying flaws on a steel strip, detecting scratches on a circuit board, or spotting imperfections on aluminum profiles, detecting surface defects ensures that products are both visually and functionally sound before they reach the end-user.

Traditionally, surface defect detection relied heavily on manual inspection or simple machine vision systems, both of which have significant limitations. Manual inspections are time-consuming and prone to human error, especially in large-scale manufacturing settings. On the other hand, conventional machine vision systems, while faster, often struggle to identify complex surface defects, particularly when dealing with various textures, lighting conditions, or small defect sizes.

Challenges in Traditional Methods

- Inconsistency in accuracy: Manual inspections can vary greatly depending on the inspector’s experience and fatigue levels.

- Limited scope of detection: Simple machine vision systems are typically calibrated for specific defect types, making them less adaptable to a wide range of defect categories.

- High cost and inefficiency: Both manual and machine vision methods can be resource-intensive, requiring significant human involvement or specialized equipment.

How Deep Learning Revolutionizes Defect Detection

Deep learning has redefined the approach to surface defect detection. With deep neural networks, machines are now capable of detecting defects more accurately, quickly, and across a broader spectrum of surface types. These models can analyze images at multiple scales, detect subtle imperfections, and continuously improve through automated learning processes. As a result, deep learning models offer:

- Higher accuracy and precision.

- Real-time defect detection capabilities.

- The ability to handle complex backgrounds and variable conditions, like changing lighting or surface textures.

Deep learning also supports the detection of micro-level defects, which are often missed by traditional methods, making it ideal for high-precision industries such as electronics, automotive, and aerospace.

Why Deep Learning for Defect Detection?

When considering the application of deep learning to industrial surface defect detection, the benefits are extensive and transformative. Not only do these techniques enhance the speed and accuracy of detection, but they also introduce a new level of adaptability that was previously unattainable.

Key Benefits of Deep Learning in Defect Detection

- Real-time processing: Deep learning algorithms can process high volumes of image data in real-time, making them suitable for continuous production lines where speed is crucial.

- Adaptability to different surfaces: Unlike traditional methods, deep learning models can be trained on diverse datasets to handle a variety of surface materials, defect types, and conditions, improving overall defect coverage.

- Improved accuracy and precision: Using advanced techniques such as multi-scale feature fusion and attention mechanisms, deep learning models can better distinguish between normal and defective products, even when defects are small or hard to see.

Key Advancements and Milestones in Deep Learning

Deep learning-based surface defect detection has rapidly evolved, introducing key innovations:

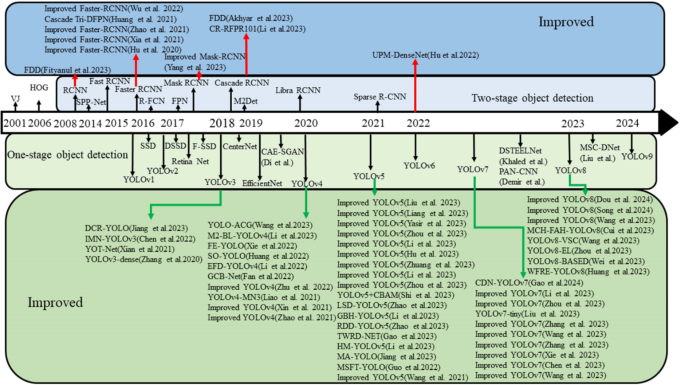

- YOLO (You Only Look Once): This family of models revolutionized object detection with its real-time processing capabilities, particularly in detecting defects on steel and PCB surfaces. YOLOv5, for example, significantly improved both detection speed and accuracy by incorporating Mosaic data augmentation and adaptive anchor boxes.

- Faster R-CNN: Known for its high accuracy in detecting complex defects, Faster R-CNN has set the benchmark for precision in industries where fine defect differentiation is critical.

- Attention mechanisms: The integration of mechanisms like CBAM (Convolutional Block Attention Module) has enhanced the ability of models to focus on critical regions within an image, improving their capacity to detect small or subtle defects.

Key Takeaways

- Deep learning offers unparalleled accuracy and adaptability for surface defect detection in industrial applications.

- Models like YOLOv5 and Faster R-CNN are leading the way in transforming defect detection into a real-time, high-precision process.

- Incorporating advanced features like multi-scale feature fusion and attention mechanisms is key to improving detection rates, especially for complex and micro-level defects.

As we delve deeper into this topic, the next section will explore the deep learning models used for surface defect detection. Specifically, we will analyze how one-stage detection algorithms like YOLOv4, YOLOv5, and YOLOv7 have revolutionized real-time defect detection in industrial settings and compare their performance across different parameters.

Deep Learning Models for Surface Defect Detection

One-Stage Detection Algorithms

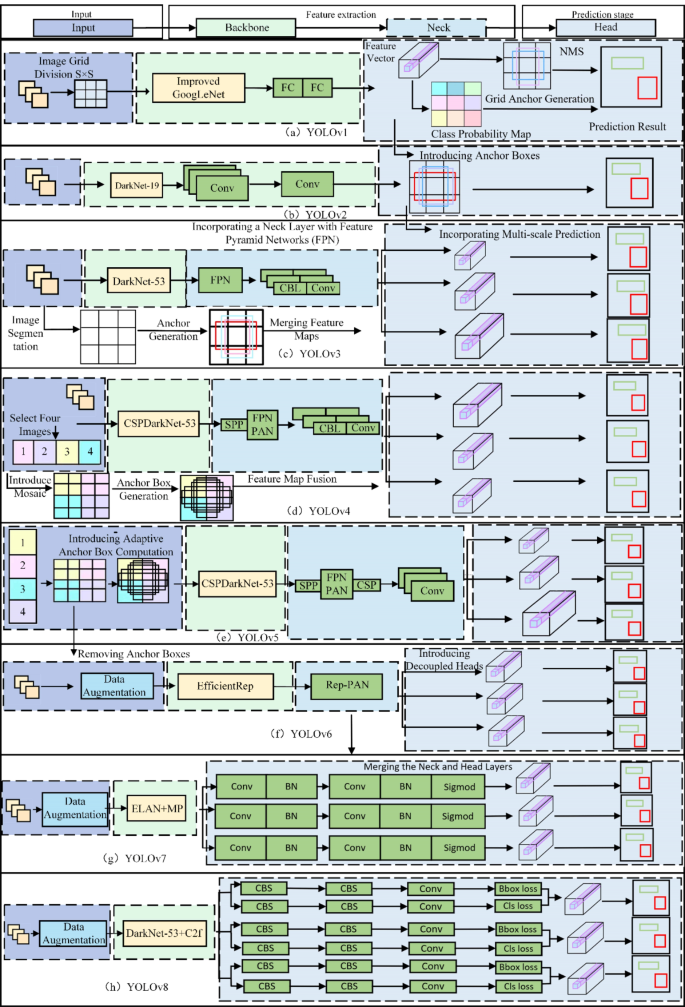

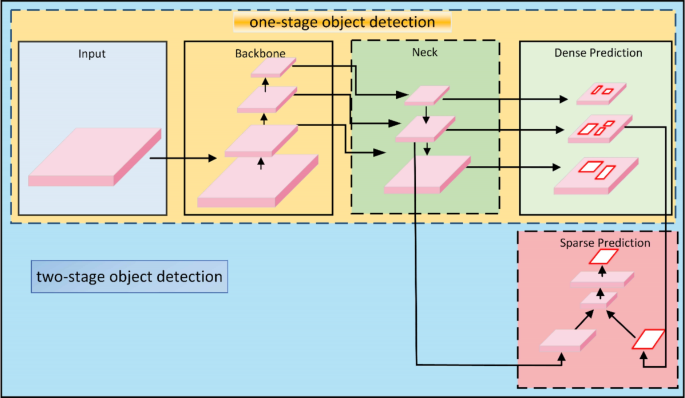

One-stage detection algorithms have dramatically transformed surface defect detection by offering real-time solutions with minimal computational requirements. These models, unlike their two-stage counterparts, perform object localization and classification in a single step, enabling faster processing times without sacrificing much on accuracy. Let’s explore how some of the most prominent one-stage models—YOLOv4, YOLOv5, and YOLOv7—have reshaped the industrial landscape.

YOLOv4: A Game-Changer in Real-Time Detection

YOLOv4 (You Only Look Once version 4) was a significant leap forward in object detection when it was introduced. This model brought together multiple optimization techniques, including CSPDarknet53, SPP (Spatial Pyramid Pooling), and PANet. These advancements enabled it to achieve a delicate balance between speed and accuracy, making it ideal for detecting defects in fast-paced industrial environments.

( YOLOv4 ) Key Features

-

- CSPDarknet53 as the backbone: Enhances feature extraction.

- SPP block: Ensures better multi-scale detection.

- PANet: Improves feature fusion from different network layers, resulting in more precise defect detection.

YOLOv4 is especially useful in industries where real-time feedback is essential for maintaining high-quality production, such as in automotive manufacturing or electronics. Its ability to deliver high FPS (Frames Per Second) without a major compromise in accuracy has made it a preferred model for many.

Building on Success

YOLOv5 took the success of its predecessor even further by introducing lighter models with improved accuracy. This version is more flexible, offering a range of model sizes—from YOLOv5s (small) to YOLOv5x (extra-large)—each catering to different computational capabilities and accuracy requirements.

Key Improvements:

-

- Adaptive anchor boxes: Improves bounding box predictions, making it more efficient in defect localization.

- Mosaic data augmentation: Enriches training data, making the model more robust in identifying defects under different lighting conditions or backgrounds.

In real-world industrial scenarios, YOLOv5 has proven to be highly efficient for detecting surface defects on steel, aluminum, and printed circuit boards (PCBs). With an improved mAP (mean Average Precision) and enhanced frame rates, this model is widely adopted in industries where precision is non-negotiable.

YOLOv7: Precision Meets Speed

As the latest iteration in the YOLO series, YOLOv7 introduced further refinements to address the limitations of previous versions. It focused on optimizing both speed and accuracy by integrating advanced mechanisms such as E-ELAN (Efficient Layer Aggregation Networks) and ConvNeXt modules for better feature extraction.

( YOLOv7 ) Key Features:

-

- E-ELAN modules: Improves gradient flow and strengthens the network’s learning capacity.

- ConvNeXt: Enhances feature learning, particularly beneficial for complex surface defects.

When tested in industrial environments, YOLOv7 exhibited superior performance in detecting defects in steel surfaces, plastic labels, and magnetic tiles. The model’s optimized structure allows it to achieve high precision while maintaining real-time detection, making it suitable for high-throughput production lines.

Comparative Analysis: YOLOv4, YOLOv5, and YOLOv7

| Model | mAP @0.5 | FPS | Key Application |

|---|---|---|---|

| YOLOv4 | 88.4% | 65 | Automotive, Steel Defects |

| YOLOv5 | 92.1% | 73 | PCBs, Aluminum Defects |

| YOLOv7 | 93.6% | 80 | Plastic, Magnetic Tiles |

- YOLOv7 outperforms the earlier versions in terms of mAP and FPS, making it a clear choice for industries requiring both speed and precision.

- YOLOv5 is more flexible in terms of deployment, offering different model sizes for varied computational capacities.

- YOLOv4, while slightly less accurate, is still highly valued for its efficiency in scenarios where speed is paramount.

Two-Stage Detection Algorithms

While one-stage models like YOLO have set the benchmark for real-time defect detection, two-stage algorithms offer superior accuracy, especially in complex industrial scenarios. These models break down the detection process into two stages: region proposal and object classification, allowing for more granular detection of defects.

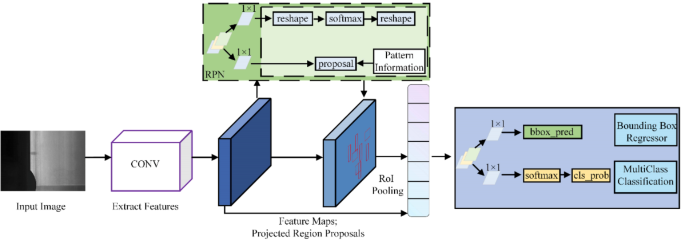

Faster R-CNN: Precision at a Cost

Faster R-CNN (Region-based Convolutional Neural Networks) is one of the most powerful models when it comes to detecting complex defects. Unlike one-stage models, Faster R-CNN generates region proposals and then classifies objects, resulting in high accuracy, especially for detecting defects in challenging environments.

Advantages:

-

- High precision for detecting small and intricate defects.

- Can handle complex surfaces and non-uniform defect patterns.

However, the computational complexity of Faster R-CNN can be a drawback. It requires more processing power, making it less suitable for real-time detection unless optimized for specific tasks. Industries that prioritize accuracy over speed—like aerospace or medical equipment manufacturing—often opt for this model.

Mask R-CNN: The Best of Both Worlds

Mask R-CNN builds upon the success of Faster R-CNN by adding a masking feature to each detected object. This is particularly useful in cases where defects need to be precisely segmented rather than just classified. For example, when detecting cracks in metallic surfaces or scratches on glass, Mask R-CNN offers a detailed analysis of the defect’s shape and size.

Advantages:

-

- Provides pixel-level defect detection, making it ideal for applications requiring precise segmentation.

- Can identify multiple defect types within a single image, making it highly versatile.

The downside is, like Faster R-CNN, Mask R-CNN is computationally demanding, requiring advanced hardware for real-time performance.

Comparison of Two-Stage Models

| Model | Accuracy (mAP @0.5) | Use Case | Speed |

|---|---|---|---|

| Faster R-CNN | 94.3% | Aerospace, Medical Equipment | Medium |

| Mask R-CNN | 96.1% | Precision Segmentation | Slow |

Both Faster R-CNN and Mask R-CNN are excellent choices for industries that cannot compromise on accuracy, but they come at the cost of speed and computational power.

Key Takeaways

- One-stage models like YOLOv5 and YOLOv7 offer a balance between speed and accuracy, making them suitable for real-time defect detection in fast-paced industrial settings.

- Two-stage models such as Faster R-CNN and Mask R-CNN are better suited for complex defect detection tasks, particularly where precision is more important than speed.

- Choosing between one-stage and two-stage models depends largely on industry-specific requirements, such as whether the focus is on real-time detection or high precision.

As we move into the next section, we will explore innovative methods and enhancements that have further optimized surface defect detection models. These enhancements include the integration of attention mechanisms, advanced loss functions, and data augmentation techniques that improve the accuracy and robustness of models across diverse industrial applications.

Innovative Methods and Enhancements for Surface Defect Detection

As industries evolve and the demand for precise surface defect detection intensifies, innovation in deep learning models has become essential. Several advancements and enhancements have optimized models for industrial applications, significantly improving both accuracy and speed. From integrating novel architectures to applying new techniques like multi-scale feature fusion and data augmentation, these innovations are paving the way for more effective and scalable defect detection systems.

Model Enhancements for Industrial Applications

To adapt to the increasingly complex needs of industrial defect detection, researchers have introduced various enhancements to existing deep learning models. These improvements focus on augmenting feature extraction, improving the model’s focus on small defects, and boosting the overall efficiency of the detection process.

CSPDarknet53: Strengthening Feature Extraction

One of the notable improvements in industrial defect detection is the integration of CSPDarknet53 into models like YOLOv4. CSPDarknet53, a variant of the Darknet backbone, optimizes gradient flow within the network by segmenting the feature map and allowing for cross-stage partial connections. This enhances the model’s capacity to extract rich feature representations without overwhelming the system’s computational resources.

Benefits:

-

- Improves multi-scale feature extraction.

- Reduces computational load, allowing for real-time detection in industrial settings.

This improvement is crucial for detecting complex defects that appear across different scales and textures, particularly in industries like automotive manufacturing and electronics.

BiFPN and PANet: Enhancing Feature Fusion

Feature fusion is a critical component of object detection models, allowing them to combine information from different layers to create more accurate predictions. Two key innovations in this space are BiFPN (Bidirectional Feature Pyramid Network) and PANet (Path Aggregation Network).

- BiFPN: Introduced in models like EfficientDet, BiFPN allows for bidirectional feature fusion with weighted connections, enabling the model to give more importance to relevant features. This is particularly useful for defects that may be challenging to detect due to non-uniform backgrounds or poor lighting conditions.

- PANet: This network enhances information flow between layers, improving the model’s ability to localize small defects and track subtle variations in the surface.

Both of these methods significantly improve the model’s performance when detecting defects in multi-textured surfaces such as ceramics, metals, and fabrics, where precision is critical.

Attention Mechanisms: Targeting Smaller Defects

Incorporating attention mechanisms like CBAM (Convolutional Block Attention Module) and GAM (Global Attention Mechanism) has proven to be a major step forward in refining defect detection models. These mechanisms help the network focus on important regions of an image, allowing for more accurate detection of small or subtle defects that would otherwise go unnoticed.

- CBAM: This module improves defect detection by applying spatial and channel-wise attention, making it easier to detect minor imperfections in a noisy background.

- GAM: GAM extends this approach by considering global context, improving the model’s sensitivity to tiny defects that are critical in industries such as aerospace and precision electronics.

Advanced Loss Functions for Bounding Box Prediction

Accurate prediction of bounding boxes is essential for detecting surface defects. To achieve this, advanced loss functions like GIOU (Generalized Intersection over Union), DIOU (Distance Intersection over Union), and SIOU (Scaled Intersection over Union) have been integrated into defect detection models.

- GIOU: Helps improve the accuracy of bounding boxes by accounting for the shape and size of the defect, especially when the defect is irregular.

- DIOU: Adds a focus on distance between the objects, enhancing the detection of defects that are closely spaced.

- SIOU: Further optimizes the prediction by considering aspect ratio changes, which is critical for detecting elongated defects like scratches or cracks.

These loss functions have enabled more precise localization of defects, which is particularly useful in industries such as metal processing and semiconductor manufacturing, where even minor inaccuracies in detection can result in significant quality issues.

Optimizing Defect Detection Models

Optimization of deep learning models is vital for ensuring fast processing speeds without compromising on accuracy, especially in real-time industrial environments. Several techniques and lightweight models have been developed to address this need, including data augmentation methods and the use of lightweight architectures.

Mosaic Data Augmentation

One of the most impactful methods for enhancing the robustness of defect detection models is Mosaic data augmentation. This technique combines four different images into one, allowing the model to learn from a wider variety of scenarios and backgrounds in a single training pass. This makes the model more adaptable to detecting defects in challenging environments with changing light conditions, reflective surfaces, or unusual angles.

Advantages:

-

- Significantly increases the variety of training samples.

- Helps the model become more resilient to unexpected scenarios during real-time defect detection.

Multi-Scale Feature Fusion

Multi-scale feature fusion is a key technique that allows models to detect defects at different scales. This is particularly useful when detecting both large, prominent defects and small, subtle imperfections in the same image. By fusing features from multiple layers of the neural network, this technique ensures that the model can identify and localize defects more accurately across different sizes and types of surfaces.

Lightweight Models: DSConv, GhostConv, and ShuffleNet

In industrial settings where speed and efficiency are crucial, lightweight models like DSConv (Depthwise Separable Convolutions), GhostConv, and ShuffleNet have proven to be extremely effective. These models reduce the number of parameters and computational requirements without sacrificing detection accuracy.

- DSConv: Splits convolution into depthwise and pointwise operations, reducing computational complexity and making it ideal for real-time applications.

- GhostConv: Creates fewer feature maps, reducing the overall computational cost while maintaining high detection accuracy.

- ShuffleNet: Applies channel shuffling to reduce the number of parameters, making it well-suited for edge devices and low-power applications.

These models allow defect detection systems to run on low-powered devices while maintaining a high degree of accuracy and speed. This is particularly important in industries that rely on on-site detection using mobile or embedded systems, such as smart manufacturing and automated quality control.

Key Takeaways

- Model enhancements like CSPDarknet53, BiFPN, and PANet have significantly improved the accuracy and efficiency of deep learning models in surface defect detection.

- Attention mechanisms such as CBAM and GAM are crucial for improving detection of small defects.

- Advanced loss functions like GIOU, DIOU, and SIOU improve bounding box accuracy, ensuring precise defect localization.

- Mosaic data augmentation and multi-scale feature fusion techniques enhance model robustness and detection accuracy across various industrial environments.

- Lightweight models such as DSConv, GhostConv, and ShuffleNet optimize performance for real-time and low-power industrial applications.

In the next section, we will delve into unsupervised and semi-supervised approaches for surface defect detection, focusing on how models like AutoEncoders and GANs play a pivotal role in identifying defects without the need for large, annotated datasets. We’ll also explore real-world case studies demonstrating the success of these approaches in PCB and steel defect detection.

Unsupervised and Semi-Supervised Approaches to Surface Defect Detection

As the field of surface defect detection continues to evolve, unsupervised and semi-supervised learning approaches are gaining traction. These methods are especially valuable in industrial applications where large, labeled datasets are difficult to obtain. By utilizing deep learning techniques such as AutoEncoders and Generative Adversarial Networks (GANs), these models offer flexibility and efficiency without the need for exhaustive data annotation. In this section, we’ll explore how these innovative techniques work and why they’re becoming critical in modern defect detection systems.

Unsupervised Defect Detection

Unsupervised defect detection models identify anomalies or defects without the need for labeled training data. This offers a solution to the challenge of obtaining large datasets that are not only difficult to annotate but also time-consuming and expensive to create. Through unsupervised learning, models can recognize patterns and irregularities that distinguish between normal and defective surfaces.

The Role of AutoEncoders in Defect Detection

One of the most prominent unsupervised learning techniques in defect detection is the AutoEncoder. AutoEncoders work by learning a compressed representation of the input data (such as an image of a defect-free surface) and then attempting to reconstruct the original input. Any reconstruction errors highlight discrepancies that may indicate defects.

Key benefits

-

- No need for labeled data: AutoEncoders work without pre-labeled datasets, making them ideal for scenarios where labeling is either costly or impractical.

- Good for anomaly detection: AutoEncoders excel at detecting anomalies, such as defects, by identifying differences between expected and observed outputs.

In the context of surface defect detection, AutoEncoders have shown great potential in identifying subtle issues like scratches or cracks that traditional detection methods might overlook.

Generative Adversarial Networks (GANs) in Unsupervised Defect Detection

GANs are another powerful tool in the unsupervised defect detection landscape. GANs consist of two neural networks—a generator and a discriminator—that work against each other to improve the quality of the data generated. The generator creates synthetic data that is as close as possible to the real-world data, while the discriminator evaluates the authenticity of the generated data.

In surface defect detection, GANs are used to:

- Generate synthetic images of surfaces with defects.

- Train models to detect irregularities without needing a massive dataset of defective samples.

This approach not only enhances the model’s learning capabilities but also allows it to better generalize across various types of surface defects, from minor imperfections to more severe faults.

Benefits and Limitations of Unsupervised Models

Unsupervised learning models are particularly useful in industrial environments where obtaining labeled defect data is either difficult or impossible. However, these models come with certain challenges:

Benefits:

-

- No labeled data required: A significant advantage, especially in industries where data labeling is expensive or infeasible.

- High flexibility: Unsupervised models can generalize across multiple defect types, even those not present in the training data.

Limitations:

-

-

- Lower precision: Without labeled data, unsupervised models can struggle to differentiate between normal variations and actual defects.

- Complex training process: These models require sophisticated architectures and substantial computational power to achieve optimal performance.

-

Case Studies: Success of Unsupervised Learning

Several case studies in various industries have demonstrated the effectiveness of unsupervised learning techniques in surface defect detection. Below are key examples illustrating the application of AutoEncoders and GANs in real-world scenarios.

Contrastive Masked AutoEncoders (CMAE) for PCB Defect Detection

In the Printed Circuit Board (PCB) industry, where surface defects like scratches and inconsistent soldering can have serious implications, Contrastive Masked AutoEncoders (CMAE) have been successfully implemented. CMAE combines masked image modeling and contrastive learning to improve the detection and classification of defects without requiring a large volume of labeled data.

Key achievements:

-

- Improved defect classification on small datasets.

- Significant reduction in false positives, which is crucial in minimizing costs during manufacturing.

DAGAN for Steel Surface Defect Detection

In the steel manufacturing industry, Dual AutoEncoder Generative Adversarial Networks (DAGAN) have shown promising results in identifying surface defects, such as cracks or corrosion. DAGAN combines the architecture of AutoEncoders with GANs to not only identify defects but also reconstruct the damaged areas.

Performance highlights:

-

- Increased accuracy in detecting small, intricate defects.

- Ability to detect defects across different lighting and background conditions.

Real-World Application in Steel and Semiconductor Manufacturing

In industries like steel production and semiconductor manufacturing, unsupervised models have consistently outperformed traditional methods. For example, in steel defect detection, unsupervised GAN-based methods achieved a remarkable balance between precision and speed, allowing for real-time monitoring on the production line.

Application benefits:

-

- Faster detection time, reducing potential bottlenecks in the manufacturing process.

- Higher accuracy rates compared to conventional techniques, especially when handling large volumes of data.

Comparison with Supervised Methods

While supervised learning models tend to outperform unsupervised ones in terms of accuracy, the flexibility and cost-effectiveness of unsupervised methods make them attractive in specific scenarios. Here’s how they compare:

Supervised learning:

-

- Requires extensive labeled data.

- Provides higher precision for well-defined tasks

Unsupervised learning:

-

-

- Ideal for anomaly detection where labeled data is unavailable.

- More adaptable to unknown defect types.

-

Despite the slightly lower accuracy, unsupervised methods are becoming increasingly popular due to their ability to scale quickly and handle diverse scenarios.

Key Takeaways

- Unsupervised models, such as AutoEncoders and GANs, are transforming surface defect detection, especially in scenarios where labeled data is scarce.

- Contrastive Masked AutoEncoders (CMAE) and DAGAN have shown remarkable success in industries like PCB and steel manufacturing.

- Unsupervised learning offers cost-effective solutions for defect detection, with the flexibility to adapt to different types of defects and industrial environments.

As the role of unsupervised learning continues to grow, it is crucial to acknowledge the challenges faced in real-world industrial applications. In the next section, we will explore the future trends and challenges that arise from integrating deep learning techniques into real-time defect detection systems, with a focus on how to balance accuracy, speed, and scalability in industrial settings.

Future Trends and Challenges in Defect Detection

As deep learning continues to transform the field of surface defect detection, the future presents both exciting opportunities and significant challenges. From the growing demand for real-time processing to the rise of new machine learning technologies, the landscape is evolving. In this section, we’ll dive into the challenges of real-world applications, explore emerging technologies, and identify the potential for deep learning to impact industries beyond manufacturing.

Challenges in Real-World Applications

Despite the impressive advancements in defect detection, there are still several hurdles to overcome, particularly when it comes to scaling these technologies in real-world industrial settings. Below are some key challenges:

Data Annotation Costs

One of the most persistent issues in supervised learning for defect detection is the high cost of data annotation. Manually labeling large datasets requires substantial time and resources, and in many industries, especially those involving complex defects or rare anomalies, collecting enough labeled data can be a bottleneck.

- Solution trends: As industries look to reduce data annotation costs, the use of semi-supervised and unsupervised techniques, such as AutoEncoders and GANs, is on the rise. These models can work with unlabeled data and improve defect detection without the need for extensive manual labeling.

Multi-Scale Defect Detection

In industries where defects come in various shapes and sizes, ensuring that models can effectively detect small, large, and irregularly shaped defects poses a significant challenge. Models must be able to handle a wide range of defect scales while maintaining accuracy.

- Current advancements: Models using multi-scale feature fusion techniques, like BiFPN and SPP-blocks, are better equipped to detect defects across multiple scales. These techniques allow for a more comprehensive field of view and enhanced feature extraction, making it easier to identify defects of all sizes.

Hardware Limitations

Deploying high-performance deep learning models in real-time industrial environments requires advanced hardware. However, many companies face limitations due to cost, scalability, or existing infrastructure. GPUs with high floating-point performance (TFLOPS) may be necessary for large-scale applications, but not every business can afford such an investment.

- Balancing speed and accuracy: Lightweight models like GhostConv and ShuffleNet are specifically designed to reduce computational demand while maintaining high detection speeds. By streamlining neural network architectures, these models make real-time processing more accessible even in resource-constrained environments.

Emerging Technologies for Enhanced Detection

Looking to the future, several emerging technologies hold the potential to further improve surface defect detection. These cutting-edge innovations are helping to address some of the existing challenges in real-world applications and pushing the boundaries of what’s possible in defect detection.

Integration of Large Language Models (LLMs)

Large Language Models (LLMs) are revolutionizing various sectors, and their impact on surface defect detection is just beginning. LLMs can be integrated with vision-based defect detection systems to streamline processes, such as automated annotation and multimodal defect detection.

- Automated annotation: With LLMs, industries can automate the annotation process, which significantly reduces the time and cost of preparing datasets for supervised learning models. LLMs can interpret descriptive natural language inputs to generate or assist in generating training data annotations.

- Multimodal detection: Combining visual and linguistic data, LLMs can perform multimodal detection, offering an additional layer of context and precision to the defect detection process.

Reinforcement Learning for Better Defect Detection

Reinforcement learning offers a promising approach for making real-time decisions in complex scenarios. By allowing models to learn optimal strategies through trial and error, reinforcement learning is ideal for environments where constant feedback and adaptation are required, such as manufacturing lines.

- Optimizing performance: Reinforcement learning can enhance defect detection by enabling systems to dynamically adjust their detection strategies based on real-time conditions, improving the model’s robustness and efficiency.

Transformers in Defect Detection

Transformers, originally designed for natural language processing, are now being adapted for computer vision tasks, including surface defect detection. These models are particularly effective at capturing global relationships within images, which is crucial for identifying defects in highly detailed industrial products.

- Enhanced feature extraction: Transformers allow models to focus on important regions within an image, improving detection accuracy, especially for small or subtle defects.

Applications Beyond Manufacturing

While deep learning models for surface defect detection have primarily been applied in manufacturing, their potential goes far beyond this sector. Here are a few key examples:

- Medical Imaging: In the medical field, defect detection algorithms are being adapted for the detection of lung nodules, tumors, and other abnormalities in medical scans, offering faster and more accurate diagnostics.

- Agriculture: Detecting defects in crops or on fruit surfaces, such as citrus epidermis issues, is crucial for maintaining product quality in the agricultural sector.

- Civil Engineering: In civil engineering, surface defect detection models are being used to identify pavement defects, cracks in infrastructure, and other issues that can compromise safety and durability.

Conclusion: The Future of Surface Defect Detection with Deep Learning

The journey through advanced surface defect detection techniques has highlighted the transformative role that deep learning plays in industrial applications. From the basics of surface defect detection and the transition to deep learning models to innovative enhancements like attention mechanisms and unsupervised learning, we’ve explored the landscape that is pushing industries toward automation and precision.

Key Recap Surface Defect Detection with Deep Learning

- Introduction to Surface Defect Detection: We began with the importance of surface defect detection in industrial manufacturing and how deep learning has revolutionized this process.

- Deep Learning Models for Surface Defect Detection: The second section delved into one-stage and two-stage detection algorithms, discussing how they bring about real-time accuracy and precision in complex scenarios.

- Innovative Methods and Enhancements: This section covered model advancements such as CSPDarknet53, BiFPN, and the integration of attention mechanisms, providing better solutions for smaller defects.

- Unsupervised and Semi-Supervised Approaches: We explored the roles of AutoEncoders and GANs in detecting defects without labeled data, highlighting the success of unsupervised learning in real-world applications.

- Future Trends and Challenges: Finally, we examined the future of defect detection, focusing on emerging technologies like LLMs, reinforcement learning, and transformers, which hold the promise of further improving defect detection accuracy, speed, and scalability.

In conclusion, the field of surface defect detection is rapidly advancing, thanks to the integration of deep learning models and emerging technologies. As industries strive for greater efficiency and precision, these advancements will continue to shape the future of quality control, ensuring that surface defect detection is faster, more reliable, and scalable across multiple industries.

FAQ: Surface Defect Detection with Deep Learning

Q: Why is surface defect detection important in industries?

A: Surface defect detection ensures product quality and prevents defective goods from reaching customers, which is critical for maintaining brand reputation and minimizing returns.

Q: How does deep learning improve defect detection accuracy?

A: Deep learning models use advanced algorithms to analyze images at multiple scales, identifying even the smallest defects with higher precision than traditional methods.

Q: Can deep learning handle different types of surfaces and defects?

A: Yes, deep learning models can be trained on diverse datasets, making them adaptable to various surfaces and defect types, from metals to semiconductors.

Q: Which model is best for real-time defect detection?

A: For real-time detection, YOLOv7 is currently the top-performing model due to its high FPS and accuracy.

Q: Are two-stage models better than one-stage models for all scenarios?

A: No, while two-stage models like Mask R-CNN provide higher accuracy, they are not ideal for real-time applications. One-stage models strike a better balance between speed and accuracy in most industrial environments.

Explore the full [Paper] for in-depth insights. All recognition and appreciation go to the brilliant researchers behind this project. If you enjoyed reading, make sure to connect with us on [Twitter, Facebook, and LinkedIn] for more insightful content. Stay updated with our latest posts and join our growing community. Your support means a lot to us, so don’t miss out on the latest updates!